It is safe to say that design changes are an integral part of the furniture construction process. On one hand, this is due to the nature of the process, which is particularly evident in the design of more complex furniture. Before the design can fully align with the designer’s ultimate vision, it is often necessary to implement various modifications and create multiple design iterations. Continue reading…

The work undertaken by the Design Unito can be divided into two distinct components: crafting the furniture model and assembling the requisite production information. Crafting a piece of furniture is a creative endeavor, the duration of which is directly contingent upon the intricacy of the piece. On the other hand, preparing information entails the mechanical task of extracting essential data from the designed furniture model, including drawings, Bill of Materials (BOMs), and, in certain cases, the development of CNC programs by the design unit. Continue reading…

It took us only 10 years to bring you this, so don’t miss your chance, because another one might not come for another 10. After lots of consideration, we’ve decided that it’s time to offer you a sweetener for each new license acquired. Therefore, all those who purchase new licenses of any type of Woodwork for Inventor (Basic, CAM, or Nesting) will receive 1 year of maintenance for free.

Benefits of the Maintenance Plan:

- New version of Woodwork for Inventor next year.

- Home user license for the entire maintenance plan validation period.

Promo starts on December 20th and ends on February 14th.

For more information, get in touch with our partners or email us at info@woodworkforinventor.com.

This term, ‘hidden design,’ characterizes situations where designers fail to provide comprehensive production information due to tool limitations or excessive workloads. Nevertheless, crafting a piece of furniture necessitates the inclusion of all essential details. Continue reading…

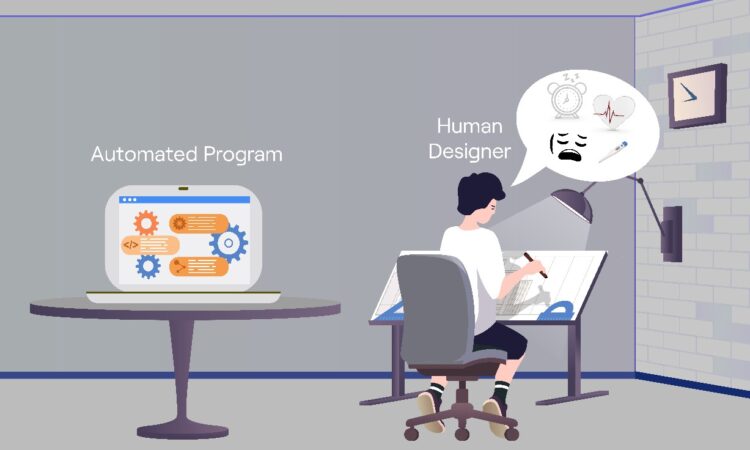

The primary source of errors in documentation stems from manual work. The distinction between automated and manual information preparation is crucial. Automated preparation is executed by a program, and if there’s an error in the program, it will consistently reproduce the same error under identical circumstances, making it relatively easy to detect and correct. On the other hand, humans are inherently variable systems, with their performance influenced by factors like mood, fatigue, and health. One day, a person may work flawlessly, while the next day, mistakes may occur. Whenever human involvement is required in any part of the documentation process, the likelihood of errors immediately increases. Continue reading…

Furniture design is undergoing a transformation, with increasing complexity in both design concepts and materials employed. Consequently, CAD systems must meet specific criteria to fulfill their role effectively:

- Capable of modeling products with intricate and unconventional structures or shapes.

- Able to model furniture using a diverse array of materials, including panels, metal, glass, wood, plastic, and more.

- Equipped to automatically convert all modeled data into production-ready information, such as Bill of Materials (BOM), drawings, and CNC programs.

The primary focus of a manufacturing company lies in the production of goods, encompassing various stages from material supply to delivery and assembly. This intricate process heavily relies on a diverse range of information that is indispensable for successful production. Consequently, each company establishes a distinct information flow, which serves to provide essential data to support the production process. Continue reading…

Another year has passed, bringing forth new challenges in an increasingly turbulent world. The global furniture industry has faced its share of obstacles, with the economic slowdown in 2023 negatively impacting consumer demand, production costs, and supply chains. However, there is a silver lining amidst the uncertainty.

According to a report by Furniture Today, the furniture market is projected to grow by 5.2% between 2023 and 2028. Continue reading…

This year, the new version of Woodwork for Inventor is introduced to the market with added features that give it another level of freedom and flexibility. Based on user requirements, we focused not on developing new functionalities, but on allowing them to customize Woodwork for Inventor to meet their needs. In this way, we allow you to create not one and not even a few features, but to adapt the software to any new demand without our help. Continue reading…

This year was special for Woodwork. A new Nesting module was launched in January, and now, as every year, we have released a new, V12 version in the spring. In this way, instead of the usual one version, we have practically released two new versions of Woodwork this year. Continue reading…