Challenges in Designing Complex Furniture

Furniture design is undergoing a transformation, with increasing complexity in both design concepts and materials employed. Consequently, CAD systems must meet specific criteria to fulfill their role effectively:

- Capable of modeling products with intricate and unconventional structures or shapes.

- Able to model furniture using a diverse array of materials, including panels, metal, glass, wood, plastic, and more.

- Equipped to automatically convert all modeled data into production-ready information, such as Bill of Materials (BOM), drawings, and CNC programs.

In cases where the existing CAD system falls short of these requirements, we often encounter the following CAD utilization scenarios within companies:

- The existing furniture CAD lacks the capability to model complex geometries, prompting the use of tools like AutoCAD or mechanical design systems such as Autodesk Inventor or SolidWorks alongside the specialized CAD. However, these systems cannot automatically generate production documentation, necessitating the manual creation of documentation from the furniture model, frequently employing software like MS Excel.

- The specialized CAD system employed can handle complex geometries but is optimized for traditional furniture materials like panels and wood. Consequently, after generating specifications using such a system, it requires manual supplementation with the missing materials.

- For all production, whether simple or complex, a universal CAD system (e.g., AutoCAD, Microstation) or a mechanical design system (e.g., Inventor, SolidWorks, SolidEdge) is utilized. While this approach offers unlimited modeling capabilities, it mandates the manual generation of production information.

Consequences:

When the CAD system lacks the capacity to encompass these requirements within a model and subsequently generate production data from it, designers must resort to manual processes and auxiliary tools.

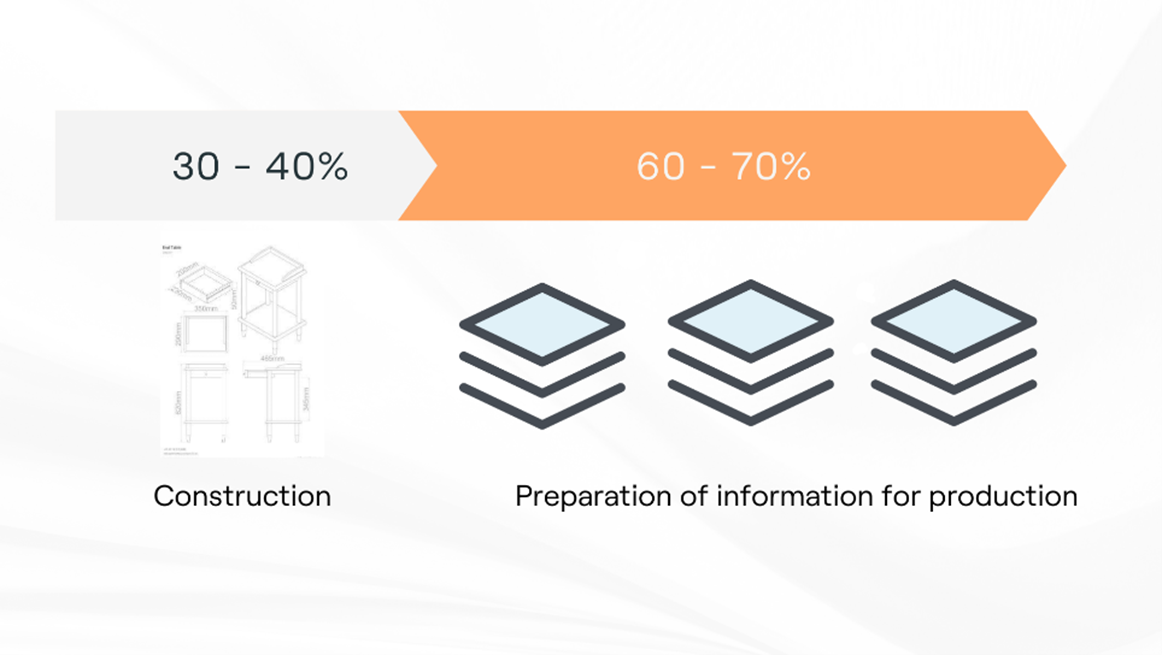

While these tools enable companies to design and manufacture complex furniture, they do so at the cost of significant manual effort by designers. Experience has shown that in such cases, designers typically allocate 30-40% of their time to product design, with the remaining 60-70% devoted to preparing all the necessary production information. In essence, designers function as estimators for half of their working hours. Due to the manual nature of this process, it often results in an unpredictable number of errors, contradicting the business objectives for the design system, which are to reduce time and minimize mistakes.

Up next:Errors in specifications and drawings. A complex process of changing the design

Up next:Errors in specifications and drawings. A complex process of changing the design