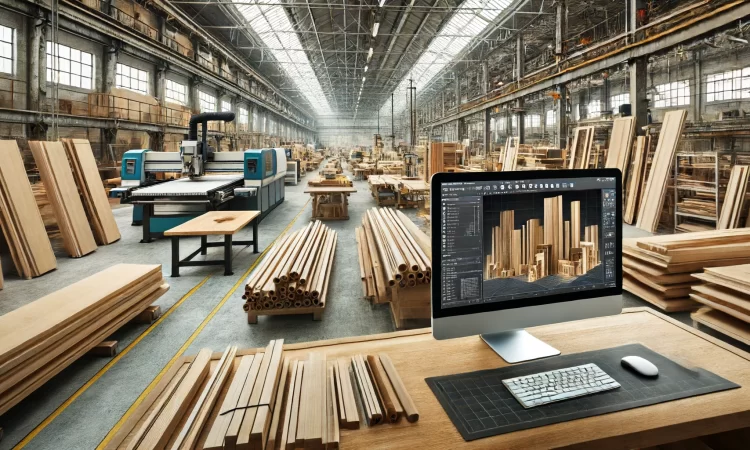

The core activity of any manufacturing company is product production, encompassing everything from material supply to delivery and assembly. This process relies on a constant flow of information; without it, production cannot take place. As a result, every company develops its own information flow to support production with the necessary data.

With growing competition, the demands on the production process are becoming more complex. This, in turn, places greater demands on the information flow—requiring it to be both comprehensive and efficient. Continue reading…