What’s new in the 7th version?

Woodwork for Inventor team is very glad to announce that the new 7th version of the software will be launched on the 19th of April. We have been developing it for the last 9 month. And now you can get acquainted with new features of the upcoming 7th version, which will be available for the Autodesk Inventor 2015, 2016 and 2017.

Automatic generation of CNC technologies

In the previous version, the user had to open the part file and use the CAM module to create CNC technology. In the new version (7) of the programme, the user may open an assembly containing the parts with attributed material of Woodwork for Inventor plug-in and launch the command for automatic generation of CNC technologies.

This command analyses the geometry of each part and automatically generates the CNC part processing technology. Thus, the user is released from performing routine tasks, because they no longer need to create CNC technology for each individual part. This new feature of Woodwork for Inventor plug-in considerably reduces the time necessary to prepare the information for production.

Other improvements with the CAM module:

- Improved spline contour calculation algorithm, now allows the processing of more sophisticated geometry of parts.

- Through drill may also serve as a blind drill. In some situations (e.g., describing the drills for side drilling), both through and blind holes may be made by the same drill. This simplifies the administration of tool database.

- An improved algorithm, which allows changing the sequence of technological operations. The user may change the position of an operation in the sequence of all operations. Previously, it was possible on a single work plane only. Moreover, the operations may be lined up according to the settings set by the user in advance.

- Woodwop post-processor contains additional information on edging of a part. Now the operator can see the edging of the part in the graphic comments of Woodwop. This considerably improves the interoperability and reduces the likelihood of errors when positioning the parts in the machine.

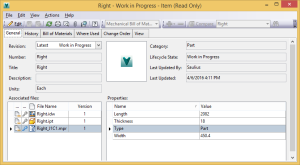

Information integration with Autodesk Vault Professional

Woodwork for Inventor may be configured so that each component, which has additional information generated by Woodwork for Inventor in the file, may automatically acquire a link to such file. For example, the file of the part gains a link to the generated CNC programme. During check-in of the component in Autodesk Vault Professional, the CNC programmes for component processing are also automatically checked in. Thus, the programmes become synchronised with the information managed by Autodesk Vault Professional. The MS Excel specification generated by Woodwork for Inventor may also be linked to the assembly file in the same manner. Woodwork for Inventor plug-in and Autodesk Vault Professional system may be configured so that the information about overall sizes of the part or any other properties generated by Woodwork for Inventor plug-in may be automatically checked in as custom properties of a component.

Woodwork for Inventor information included into Vault specification

Woodwork for Inventor can generate the Autodesk Vault Professional specification items directly and check in the information about the component generated by Woodwork for Inventor. The specification generated contains all information about the composition of parts, i.e. a part is visualised as a composite, which contains the fill workpiece, cover workpiece, etc.

The check-in mechanism correctly interprets the composition of standard components described by Woodwork for Inventor. Thus, all information about the product created may be transferred to the Autodesk Vault Professional system in the same form as represented in the Woodwork for Inventor specification generator (BOM) structure.

CNC program included into data set of item

The process of transfer of information itself is very flexible due to the possibility to configure the link between the Autodesk Vault Professional system categories with the concepts used in the Woodwork for Inventor plug-in such as fill material, cover material, etc. It facilitates the work with the material for the user. Measurement units used in the Woodwork for Inventor may also be linked to the measurement units of Autodesk Vault Professional as well as other custom properties, which have to be seen in the Autodesk Vault Professional system entry.

Automatic generation of Technical drawings

The automatic generation of technical drawings is continually improved. At present, automatic updates of the information of Woodwork for Inventor in the technical drawing are available in the following areas:

- Updated information about covers. If the cover is removed from the part model, after refreshing the technical drawing, it is no longer visualised in the drawing. If a new cover is added, the visualisation of the cover appears in the technical drawing.

- If a material configuration different from the one the technical drawing was generated with is specified, the values indicated the information fields in Woodwork for Inventor are automatically changed after refresh.

- If the overall dimensions of the model are changed, they are updated in the fields of the technical drawing containing the information of sizes (e.g., in the corner stamp).

Expanding the functions of Skeleton DressUp

The functions of skeleton dressup are being further consistently expanded:

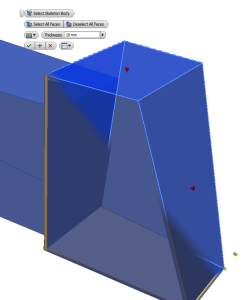

Skeleton DressUp

- Generation of panel bodies by crossing the skeleton body with the work plan is now possible.

- Improved visualisation in generating the panel body. The direction of generating the body of the part may be interactively changed in the screen.

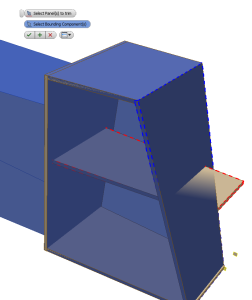

- Expanded operation of trim command, which allows crossing the panel body by work plane.

- Improved manipulation of showing and hiding the bodies. Previously, in order to show a hidden body, all of them had to be shown and the unnecessary ones had to be hidden during the next operation. Now the user may interactively choose the hidden bodies to show.

Trimming of the board

Expanded list of keywords

As the possibilities of Woodwork for Inventor are expanded, additional information occurs, which requires additional keywords for output to specifications (BOM). Therefore, new keywords have been added, which allow:

- Servicing the information about CNC technology. These keywords allow specifying the information about the jobs, clampings, basic clamping points or CNC programmes generated for the given part in the specification entry. This information may be important for automation of part label printing when cutting the workpiece.

- Linking the position numbers in the technical drawing of the compound with the entries generated in the Woodwork for Inventor specification (BOM). This allows formalizing the technical drawing of the composite, where the positions of parts are marked in the way compatible with Autodesk Inventor. The latter may also be presented in the specification (BOM) generated by Woodwork for Inventor.

- Outputting the information about the parent unit. For example, this allows requesting an output of information about the unit the given part is assigned to in the technical drawing of the part.