Maximizing Efficiency: The Importance of Effective CAD System Implementation in the Furniture Industry

The primary focus of a manufacturing company lies in the production of goods, encompassing various stages from material supply to delivery and assembly. This intricate process heavily relies on a diverse range of information that is indispensable for successful production. Consequently, each company establishes a distinct information flow, which serves to provide essential data to support the production process.

In the face of escalating competition, the demands placed on the product flow have become increasingly rigorous. Consequently, these demands necessitate information that is comprehensive and promptly available.

For a furniture company, one of the key sources of information is the CAD system. This system generates vital data concerning the product itself, facilitating essential activities such as supply, production, accounting, and management. The significance of CAD cannot be overstated as it permeates all aspects of company operations. Hence, the selection of an appropriate CAD system is critical, not only for the immediate users, such as designers and engineers, but also for the entire company.

While choosing the right CAD system is crucial for a furniture company, the implementation of the chosen solution is equally, if not more, important. Implementing the CAD system effectively ensures that the company can fully leverage its features and benefits, leading to optimized production processes and improved overall efficiency.

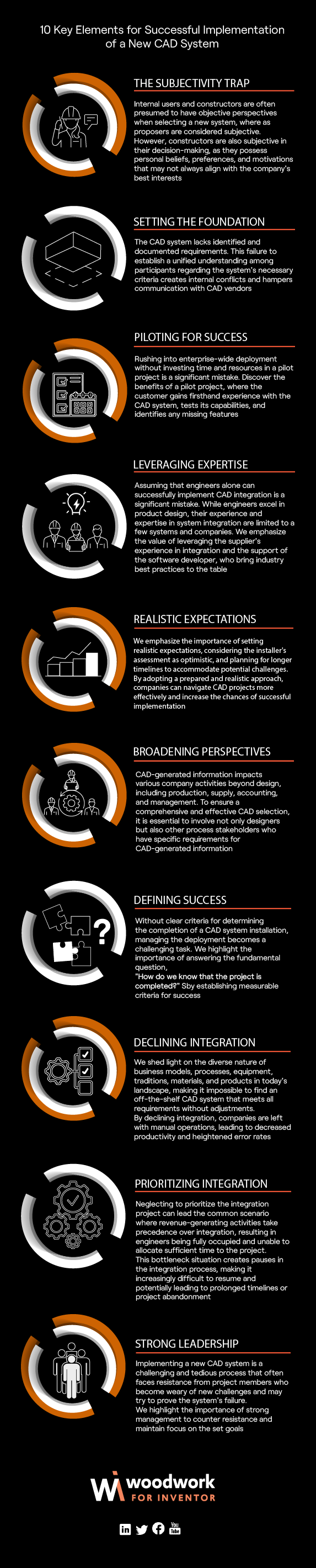

We have created a little cheat sheet for you to emphasize the importance of successful implementation and common mistakes that companies do.