Understanding the Role of Design Teams in Custom Furniture Manufacturing

In custom furniture manufacturing, the design team is essential for translating client requirements into production-ready outputs. Using tools like 3D design software and CAD/CAM systems, designers create models, technical drawings, and CNC programs that guide the production process.

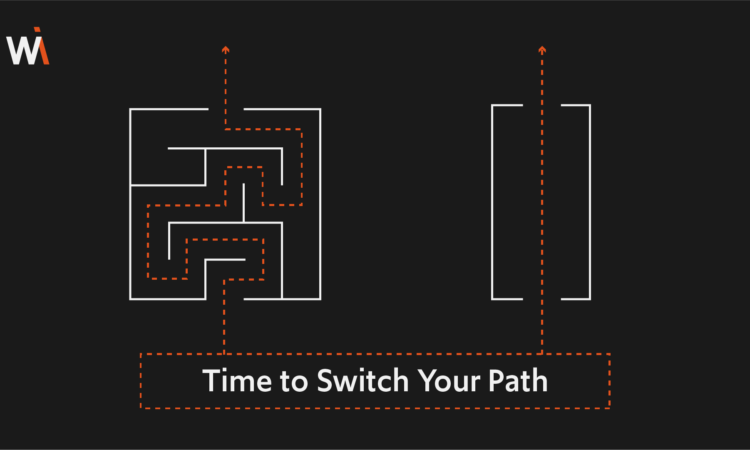

However, many C-level decision-makers don’t have the time to dive deep into the nuances of these tools and workflows. This creates a communication gap that leads to misaligned expectations, overlooked inefficiencies, and missed opportunities to optimize processes.

The Three Common Bottlenecks in Custom Furniture Manufacturing

Let’s break down the key bottlenecks that may be slowing down your production — and how to overcome them.

1. Limited Design Capabilities

Many manufacturers struggle with outdated design tools that limit their ability to create complex furniture designs or work with diverse materials. This can stifle innovation and prevent companies from meeting unique client demands.

How to Overcome It:

Modern CAD/CAM systems offer flexibility to design furniture of any complexity and work with a wide variety of materials — from panels and composite components to metal and frames. By expanding your design capabilities, your team can create more innovative, client-specific products without being held back by software limitations.

2. Time-Consuming Design Processes & Errors

Manual processes, repetitive tasks, and human-factor errors are major culprits in slowing down the design-to-production workflow. These inefficiencies not only delay production but also increase the risk of costly mistakes.

How to Overcome It:

Automating routine design tasks can save time and reduce errors. CAD/CAM tools can handle tasks such as:

- Generating technical drawings

- Creating BOM (Bill of Materials) sheets

- Preparing CNC programs

By automating these processes, you can free up your design team to focus on more complex projects and reduce the likelihood of errors that cause production delays.

3. Disjointed Design Data Flow

In many furniture manufacturing companies, design data is often fragmented across different systems. This disjointed data flow causes delays, miscommunication, and inconsistencies between design, production, and ERP/MES systems.

How to Overcome It:

Creating a seamless data flow from CAD to production ensures that everyone is working with the same accurate information. Integration between CAD/CAM tools, ERP/MES systems, and CNC equipment can eliminate miscommunication, improve traceability, and speed up production handoffs.

Bridging the Communication Gap Between Management and Design Teams

One of the biggest challenges in custom furniture manufacturing is the communication gap between C-level executivesand design teams. For decision-makers, understanding the technical details of CAD/CAM tools may seem overwhelming. However, bridging this gap is essential to reduce inefficiencies and boost productivity.

How to Bridge the Gap:

- Understand the key capabilities of your design tools

- Encourage open communication between departments

- Participate in training sessions or webinars to gain insights into workflows

By improving understanding between leadership and design teams, companies can align expectations and work more efficiently.

Join Our Webinar: Learn How to Remove Bottlenecks in Custom Furniture Manufacturing

To help you address these bottlenecks, we’re hosting a free webinar designed for CEOs, Heads of Design, and Designers in the custom furniture manufacturing industry.

Why Attend?

This webinar will help you:

- Overcome limited design capabilities to create more complex, client-specific furniture

- Reduce time-consuming tasks and human-factor errors through automation

- Create seamless data flows between design and production to speed up workflows

Date: January 30th, 2025

⏰ Time: 2 PM UTC

Format: Online Webinar

Register here: https://webinar.woodworkforinventor.com/expectations

Conclusion

Removing bottlenecks in custom furniture manufacturing requires more than just updating tools — it demands streamlined processes, better communication, and automation. By addressing limited design capabilities, time-consuming processes, and disjointed data flows, you can optimize your production workflow and stay competitive in a fast-paced market.

Ready to take the next step? Join our webinar and discover how to transform your workflow from design to production.

Sign up now: https://webinar.woodworkforinventor.com/expectations