Why Woodworkers Overlook Autodesk Inventor and Why They Shouldn’t

In the woodworking industry, traditional methods and familiar tools often dominate the landscape. Many woodworkers rely on software specifically marketed for their craft, often overlooking tools like Autodesk Inventor. This oversight can be attributed to several misconceptions. However, these misunderstandings can prevent woodworkers from experiencing the numerous advantages that Autodesk Inventor can offer. Let’s explore why people might not see Autodesk Inventor as a solution for woodworking and why this perspective is mistaken.

Misconception 1: “Autodesk Inventor is Only for Engineering and Mechanical Design”

One of the primary reasons woodworkers might overlook Autodesk Inventor is its strong association with engineering and mechanical design. This perception stems from the software’s widespread use in these fields. However, this viewpoint fails to recognize the versatility and adaptability of Inventor’s tools for woodworking applications.

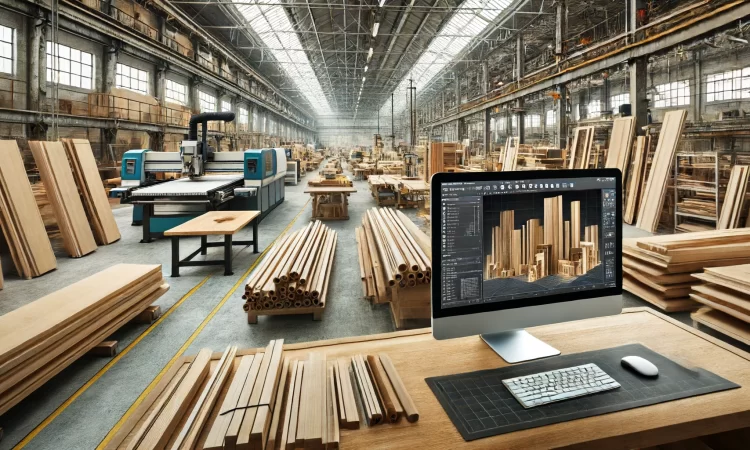

Why This is Wrong: Autodesk Inventor’s robust 3D modeling, simulation, and documentation capabilities are equally beneficial for woodworking. The precision and customization offered by Inventor can significantly enhance the quality and efficiency of woodworking projects, whether designing intricate furniture or complex wooden structures. More about the ways Autodesk Inventor can elevate Woodworing Creativity.

Misconception 2: “The Learning Curve is Too Steep”

Another common concern is the perceived complexity of Autodesk Inventor. Many woodworkers believe that mastering such a sophisticated tool would require substantial time and effort, making it an impractical choice compared to simpler, woodworking-specific software.

Why This is Wrong: While Autodesk Inventor does offer advanced features, it is also designed to be user-friendly. The software provides extensive support resources, including tutorials, forums, and customer service, to help users quickly become proficient. Moreover, the investment in learning Autodesk Inventor pays off through the increased efficiency and superior design capabilities it brings to woodworking projects.

Misconception 3: “It’s Not Tailored for Woodworking”

Woodworkers might think that Autodesk Inventor lacks features specifically designed for their industry, unlike software that is marketed directly to woodworkers. This can lead to the assumption that Inventor wouldn’t meet their specific needs.

Why This is Wrong: Autodesk Inventor, when combined with the Woodwork for Inventor add-on, offers a comprehensive solution tailored for woodworking. Woodwork for Inventor includes specialized tools such as material libraries, automated joint creation, and BOM generation that directly address the unique needs of the woodworking industry. This combination ensures that woodworkers have access to powerful, industry-specific features.

Misconception 4: “It’s Too Expensive”

Cost is often a decisive factor for small to medium-sized woodworking businesses. There is a perception that Autodesk Inventor is prohibitively expensive, especially when compared to other woodworking-specific software.

Why This is Wrong: While Autodesk Inventor is a premium tool, its cost is justified by the value it delivers. The software’s ability to reduce material waste, minimize errors, and streamline production processes results in long-term savings. Additionally, the improved product quality and design innovation can lead to higher customer satisfaction and increased business opportunities.

Breaking the Misconceptions

It’s essential to break down these misconceptions and highlight the true value that Autodesk Inventor brings to the woodworking industry:

- Versatility and Precision: Inventor’s advanced design tools ensure precision and accuracy, essential for high-quality woodworking.

- Enhanced Visualization: Detailed 3D modeling allows for thorough inspection and adjustments before production, reducing costly mistakes.

- Efficiency through Automation: Features like automated joint creation and BOM generation streamline processes and save time.

- Integration with CNC Machines: Seamless integration with CNC machines facilitates efficient and accurate production.

- Support and Learning Resources: Extensive tutorials and customer support make it easier to learn and utilize Inventor effectively.

Conclusion

The woodworking industry stands to gain significantly from adopting Autodesk Inventor. Overcoming the misconceptions about its applicability reveals a tool that offers precision, flexibility, and efficiency unmatched by many woodworking-specific software options. By embracing Autodesk Inventor, woodworkers can elevate their craft, improve productivity, and achieve superior results, making it an invaluable asset in today’s competitive market.